Suzhou's first jet loom silk brocade Song

2022-07-30 13:24

Su News (Reporter Chen Xiuya) After more than two years of trials, Jiangsu Wangong Technology Group Co., Ltd. (hereinafter referred to as “Wangong Group”) successfully developed the first jet silk Songjin loom using modern technology to innovate ancient weaving technology. Weaving silk Song Jin. Recently, the Jiangsu Silk Association Expert Committee identified that the Wangong Group's technical innovations on the upper and lower double-axle of the air-jet looms and electronic jacquard machines, double-electron delivery, double tension control, and adjustable activity delivery frames are domestic. The first. The jet silk Songjin looms are another innovation of Song Jin weaving skills after the rapier looms, injecting new vitality into the development of Song Jin industry.

The world's "non-legacy" Song Jin's production, Suzhou has always been in the leading position in the country. After liberation, Suzhou Song Jin entered the stage of industrial production. In the mid-1990s, urban industrial enterprises “returned two into three” and Song Jin produced scattered folks. As the market shrinks, Song Jin's weaving skills are complex and difficult, with fewer and fewer producers.

Silk is extremely delicate. Since ancient times, silk Song Jin has been weaving by wood weaving machine. Later, there was a shuttle iron loom that replaced manpower with machinery. In March 2012, Wujiang City Dingsheng Silk Co., Ltd. successfully transformed the Songjin Jacquard rapier loom, enabling Song Jin to enter the shuttleless weaving. Last year, the APEC meeting triggered “Song Jin Hot”, and people once again focused on Song Jin production. "In addition to the adaptation of Song Jin varieties to the market, Song Jin has long been inefficient in production and low in output, which is also a major problem that has plagued the development of Song Jinye," said Shang Damin, secretary general of the Suzhou Silk Industry Association.

Can modern air-jet looms weave silk and songs to improve efficiency? How does delicate silk withstand the high-speed impact of jets? The problem was placed before the board of directors of Wangong Group. Over the years, Jiangsu Wangong Group has developed an air-jet brocade machine and used Chinese-style landscape paintings such as Chinese landscape paintings to produce Chinese woven brocade culture products. After careful technical research, the group gradually turned its dreams into reality from 2013. Under the guidance of experts, the group made technological innovations in the structure of air-jet looms and made technical adjustments to electronic jacquard machines. After many trials, the first jet silk Song Jin loom was born in March this year.

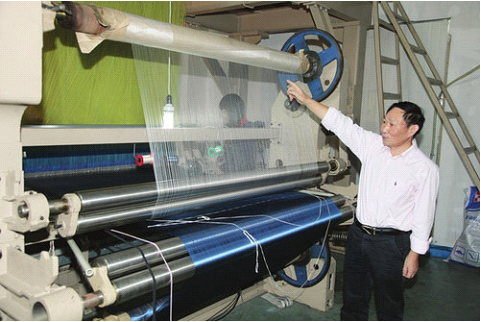

Yesterday, the reporter saw that the air-jet looms of the woven Song Jin looked very modern and the trusses were tall. Under the control of the computer, the loom runs quickly, weft insertion, beating, opening, letting, winding, etc. Song Jin weaving process is completed automatically, only the operator is inspected. At present, the project has entered the pilot stage, and the trial production of silk Song Jin has been made into cheongsam, bags, ties and household items. “Compared with the traditional shuttle looms, the efficiency of air-jet looms and brocades can be increased by about 4 times.” Song De weaving expert Li Dexi said that the speed of the rapier looms is about 250 rpm. The jet Song Jin loom can rotate up to 340 rpm, and can weave one meter of Song Jin per hour. In the past, wood weaving machines only weaved 10 centimeters a day.

It is understood that in addition to high weaving efficiency, the jet Song Jin pattern is equally expressive. Tested by the National Silk and Garment Product Quality Supervision and Inspection Center, the performance of this product complies with relevant national standards.